Aircraft Research Association

The Aircraft Research Association uses Abaqus Unifed FEA suite to assist engineers in critical decision-making.

About the client

Aircraft Research Association (ARA) was formed in 1952 by the UK’s leading aerospace companies to create a state of the art transonic wind tunnel.

What did TECHNIA do?

TECHNIA has provided many years of valuable training to ARA’s designers and CATIA users.

What were the results?

ARA has grown its customer base and now finds its test facilities booked many months in advance.

Abaqus Unified FEA suite provided most of the analysis and simulations tools required to support ARA’s products design cycle and demanding design requirements. Besides, we found that Abaqus Unified FEA open interface is readily adaptable to our in-house analysis codes.

Aircraft Research Association (ARA) was formed in 1952 by the UK’s leading aerospace companies to create a state of the art transonic wind tunnel that would maintain a dominant position within aerospace research and development.

About Aircraft Research Association (ARA)

Over time, ARA’s brief has widened and expertise broadened to include most of the world’s major aerospace companies as customers and a developing services portfolio. With the addition of Dassault Systèmes SIMULIA Abaqus, ARA underlines its commitment to maintain its position at the forefront of the UK Aerospace industry’s research and development capabilities.

Implementation of multi-physics and cross-disciplinary FEA codes

ARA is a world leader in transonic wind tunnel testing. Its customer orientated business model enables it to deliver products and services to customers’ satisfaction.

ARA recognises that its extremely complex design solutions need multi-physics and cross-disciplinary FEA codes to improve the fidelity of predicted structural performance and analytical simulations.

ARA has assessed and evaluated all mainstream FEA software.

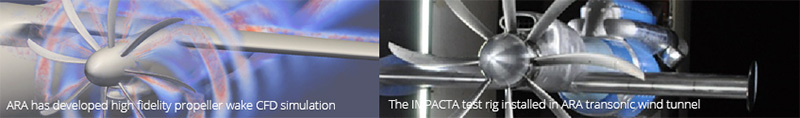

The IMPACTA (Improving the Propulsion Aerodynamics and Acoustics of Turboprop Aircraft) project

The principle aim of IMPACTA was to study propeller-airframe interaction effects using a combination of numerical simulation and scaled-model wind-tunnel testing. The aircraft under consideration is representative of current high-wing mounted turboprop regional aircraft of around 70-90 seats. A prime focus of the IMPACTA project is to study the aerodynamic interference effects due to the installation of a turboprop propulsion system on a regional aircraft.

As part of the IMPACTA_programme, ARA designed a wind tunnel test rig comprising a long and slender drive shaft to transmit torque from electric motor to a propeller subassembly. The challenge was to design a shaft having critical speed outside the test operating regime and yet have satisfactory structural strength to transmit the torque. ARA’s structural analysts effectively used the Abaqus rotor dynamics procedure and scripts available on the SIMULIA Knowledge Base to analyse structural dynamics of the shaft, generate Campbell interference diagrams and predict whirl modes.

The analysis assisted engineers in critical decision making regarding the stiffness of bearings, material selection as well as the position of the shaft supports.

ARA compared its Abaqus analysis output with the rotor shaft analysis results performed by an eminent customer who is regarded as an ultimate leader in the aero propeller industry. The analysis results correlated well with the analysis performed by the customer using their own in-house specific rotor shaft analysis dedicated code.

Supplier Selection

“TECHNIA (formerly Intrinsys) was tremendously flexible, patient and tolerant in accommodating ARA’s stringent business and procurement requirements. In addition, TECHNIA provided a courtesy Abaqus awareness course to assist ARA in the FEA selection process“, says Zdenko Uvalic, ARA.

Once the selection decision was made, TECHNIA promptly delivered an off-site training course for Abaqus users, (free of charge).

Final Point

ARA is a vibrant, exciting and research orientated establishment. Its growing customer base is a testimony to the quality of services and support they provide to its customers, partners and subcontractors. As a direct result, ARA test facilities are booked many months in advance.

ARA is planning to expand its dynamic analysis capability and dynamic test data acquisition methods. In addition, it will be developing its current aero-elasticity analysis and test facilities by performing co-simulations linking Abaqus and Tau (CFD code developed by DLR).

ARA and TECHNIA co-operation has an extensive and well-founded heritage dating back from procuring CATIA licenses from Applied (TECHNIA since 2014), providing valuable training to ARA’s designers and CATIA users. TECHNIA currently provides ARA with Abaqus licences as well as CATIA licences.

“We’ll certainly continue to use TECHNIA reputable expertise to train and provide technical support to our designers and structural analysts. We also purchase additional CATIA licenses on ad-hoc bases from TECHNIA when our workload demands increase,“ Zdenko Uvalic, ARA.

We provide top-tier engineering design software, turnkey solutions and expert consultancy.